CNC Machining ke Eng?

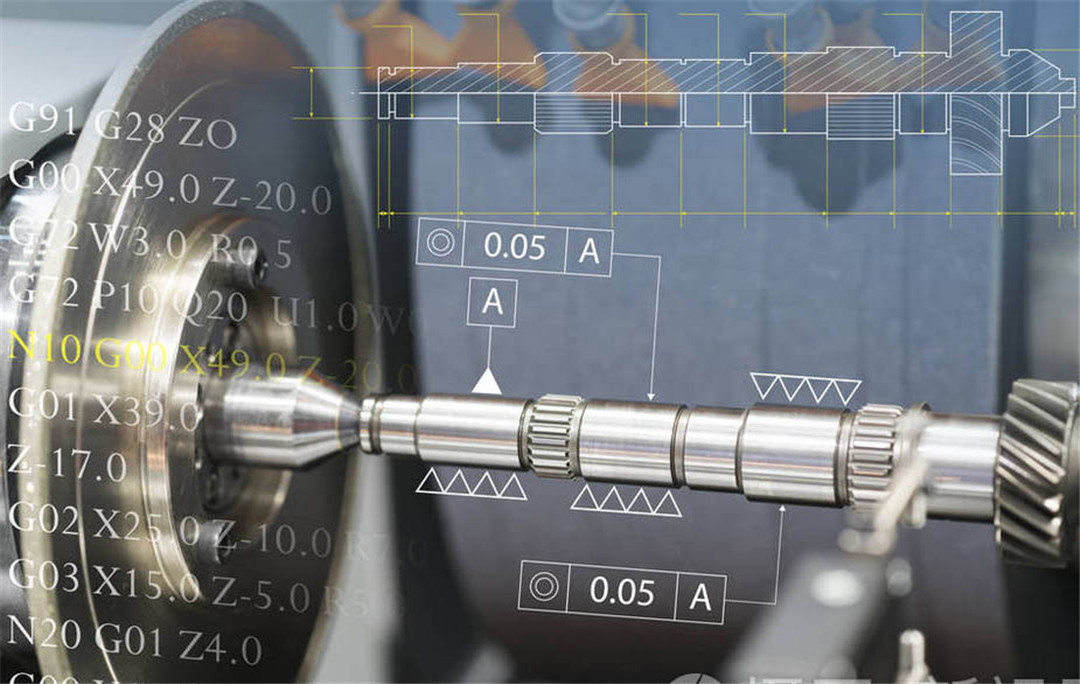

CNC machining ke ts'ebetso ea tlhahiso e sebelisang litsamaiso tsa komporo ho sebetsa le ho qhekella mochini le lisebelisoa tsa ho seha ho bopa thepa ea thepa - mohlala, tšepe, polasetiki, lehong, foam, composite, joalo-joalo - ka likarolo le meralo.Le ha ts'ebetso ea mochini oa CNC e fana ka bokhoni le ts'ebetso e fapaneng, melaoana ea mantlha ea ts'ebetso e lula e ts'oana ho tsona kaofela.

CNC machining process e loketse mefuta e fapaneng ea liindasteri, ho kenyeletsoa likoloi, sefofane, kaho le temo, mme e khona ho hlahisa lihlahisoa tse ngata, joalo ka liforeimi tsa autombile, lisebelisoa tsa ho buoa, lienjineri tsa sefofane, likere joalo-joalo.Ts'ebetso ena e kenyelletsa lits'ebetso tse fapaneng tse laoloang ke komporo-ho kenyeletsoa mekhoa ea mochini, ea lik'hemik'hale, ea motlakase le ea mocheso-e tlosang lisebelisoa tse hlokahalang ho tsoa ho workpiece ho hlahisa karolo kapa sehlahisoa se entsoeng ka tloaelo.

CNC Machining e sebetsa joang?

Ts'ebetso ea mantlha ea mochini oa CNC e kenyelletsa mekhahlelo e latelang:

Ho theha mohlala oa CAD

Ho fetolela faele ea CAD ho lenaneo la CNC

Ho lokisa mochine oa CNC

Ho etsa ts'ebetso ea mochini

Ha sistimi ea CNC e kentsoe tšebetsong, likheo tse lakatsehang li hlophisoa ka har'a software 'me li laeloa ho lisebelisoa le mochini o tsamaisanang, o etsang mesebetsi ea boholo joalo ka ha ho boletsoe, joalo ka roboto.Lenaneong la CNC, jenereithara ea khoutu ka har'a sistimi ea linomoro hangata e tla nka hore mekhoa ha e na sekoli, leha ho na le monyetla oa liphoso, e leng kholoanyane neng kapa neng ha mochini oa CNC o lebisitsoe ho khaola ka lehlakoreng le le leng ka nako e le 'ngoe.Ho beoa ha sesebelisoa tsamaisong ea taolo ea linomoro ho hlalosoa ke letoto la lintho tse kenang tse tsejoang e le lenaneo la karolo.

Ka mochine oa ho laola lipalo, mananeo a kenngoa ka likarete tsa punch.Ka lehlakoreng le leng, mananeo a mechine ea CNC a feptjoa lik'homphieutha ka li-keyboards tse nyenyane.Lenaneo la CNC le bolokoa mohopolong oa komporo.Khoutu ka boeona e ngotsoe le ho hlophisoa ke baetsi ba mananeo.Ka hona, litsamaiso tsa CNC li fana ka matla a khomphutha a pharalletseng haholo.Habohlokoa le ho feta, litsamaiso tsa CNC ha li eme ho hang kaha likhothaletso tse ncha li ka eketsoa mananeong a neng a le teng pele ka khoutu e ntlafalitsoeng.

Mefuta ea CNC Machining Operations CNC Turning

CNC Turning ke ts'ebetso ea machining e sebelisang lisebelisoa tsa ho itšeha tse nang le ntlha e le 'ngoe ho tlosa lisebelisoa ho tloha ho sesebediswa se potolohang.Bokhoni ba ts'ebetso ea mokhoa oa ho reteleha bo kenyelletsa ho tena, ho shebana, ho grooving, le ho seha likhoele.Mechineng ea lathe, likotoana li khaoloa ka tsela e selikalikoe ka lisebelisoa tsa indexable.Ka theknoloji ea CNC, likheo tse sebelisoang ke li-lathe li etsoa ka nepo le lebelo le phahameng.Li-lathe tsa CNC li sebelisoa ho hlahisa meralo e rarahaneng e neng e ke ke ea khonahala mefuteng ea mochini e tsamaisoang ka letsoho.Ka kakaretso, mesebetsi ea taolo ea li-mill le li-lathes tsa CNC li tšoana.Joalo ka li-mill tsa CNC, li-lathes li ka tsamaisoa ke G-code kapa khoutu e ikhethang ea mong'a ntlo.Leha ho le joalo, boholo ba li-lathes tsa CNC li na le lilepe tse peli - X le Z.

CNC Milling

CNC Milling ke ts'ebetso ea machining e sebelisang lisebelisoa tse pota-potileng tsa ho seha lintlha tse ngata ho tlosa thepa ho tsoa ho workpiece.Li-mill tsa CNC li khona ho sebetsa ka mananeo a nang le lintlha tse mabapi le linomoro le litlhaku tse tataisang likotoana tsa libaka tse fapaneng.Lenaneo le sebelisitsoeng bakeng sa mochini oa leloala le ka ipapisa le Gode kapa puo e 'ngoe e ikhethang e hlahisitsoeng ke sehlopha, Basic m-cos e na le sistimi ea li-axis tse tharo (X, Y le Z), le hoja boholo ba limilo tse ncha li ka amohela lilepe tse ling tse tharo.Bokhoni ba ts'ebetso ea ts'ebetso ea ho sila bo kenyelletsa sefahleho-ho seha li-slots tse sa tebang, libaka tse bataletseng le li-cavitite tse bataletseng ka har'a sesebelisoa-le likheo tse tebileng tsa tšilo, joalo ka li-slots le likhoele, ho etsa mosebetsi.

5 Mochini oa li-axis

The 3, 4, kapa 5 axis machining e hlalosoa e amana le palo ea litaelo tseo sesebelisoa sa ho itšeha se ka tsamaeang ho sona, sena se boetse se lekanyetsa bokhoni ba mochine oa CNC ho tsamaisa mosebetsi le sesebelisoa.Litsi tsa machining tsa 3-axis li ka tsamaisa karolo ka tsela ea X le Y mme sesebelisoa se ea holimo le tlase haufi le Z-axis, ha setsing sa machining sa 5 axis, sesebelisoa se ka tsamaea ka mose ho lilepe tsa X, Y le Z hammoho le e potoloha ka lilepe tsa A le B, e leng se etsang hore sehahi se khone ho atamela workpiece ho tloha ka tsela leha e le efe le lehlakoreng leha e le lefe.5 axis machining e fapane le machining a mahlakore a 5.Ka hona, lits'ebeletso tsa machining tsa 5 axis CNC li lumella menyetla ea infinte ea likarolo tse entsoeng ka mochini.Ho sebetsa ka holim'a hook, machining a sa tloaelehang a sebopeho, machining a se nang letho, ho phunya, ho seha oblique, le lisebelisoa tse ling tse ikhethang li ka ba le ts'ebeletso ea machining ea 5 axis CNC.

Mochini oa mofuta oa Switzerland

Mochine oa mofuta oa Switzerland o bitsoa machining ka lathe ea mofuta oa Switzerland kapa lathe ea othomathike ea Switzerland, ke mochini oa sejoale-joale o nepahetseng o ka hlahisang likarolo tse nyane haholo kapele le ka nepo.

Mochini oa Switzerland o sebetsa ka ho fepa li-bar stock ka bushing ea tataiso, e ts'ehetsang thepa ka thata ha e ntse e fepa sebakeng sa lisebelisoa tsa mochini.

Ha ho bapisoa le li-lathe tsa traidtional automatic lathes tsa mofuta oa Switzerland li na le bokhoni bo ikhethang ba ho hlahisa likarolo tse nyane haholo, tse nepahetseng ka lebelo le potlakileng.Motsoako oa ho nepahala ho phahameng le boleng bo phahameng ba tlhahiso e etsa hore mechine ea Switzerland e be karolo ea bohlokoa ea lisebelisoa bakeng sa mabenkele a lokelang ho hlahisa palo e kholo ea likarolo tse nyenyane le tse rarahaneng tse nang le moeli o fokolang bakeng sa phoso.

Lintho tse sebelisoang ho CNC Machining Kopo

Leha ho na le mefuta e mengata ea lisebelisoa tseo u ka li sebelisang mochining oa CNC, lisebelisoa tse sebelisoang haholo ke:

Lisebelisoa tsa Aluminium

● Al 6061-T6

● Al6063-T6

● Al7075-T6

● Al5052

● Al2024

Lisebelisoa tsa tšepe e sa hloekang:

● Tšepe e sa hloekang 303/304

● Tšepe e sa hloekang 316/316L

● Tšepe e sa hloekang 420

● Tšepe e sa hloekang 410

● Tšepe e sa hloekang 416

● Tšepe e sa hloekang 17-4H

● Tšepe e sa hloekang 18-8

Plastiki:

● POM (Delrin),ABS (Acrylonitrile Butadiene Styrene)

● HDPE, Nylon(PA),PLA,PC (Polycarbonate)

● PEEK (Polyether Ether Ketone)

● PMMA (Polymethyl Methacrylate kapa Acrylic)

● PP (Polypropylene)

● PTFE (Polytetrafluoroethylene)

Lisebelisoa tsa Copper & Brass:

● Koporo 260

● Koporo 360

● H90, H80, H68, H62

Lisebelisoa tsa tšepe tsa carbon:

● Tšepe 1018, 1024, 1215

● Tšepe 4140, 4130

● Tšepe A36…

Lisebelisoa tsa Titanium:

● Titanium (Kereiti 2)

● Titanium (Kereiti ea 5)

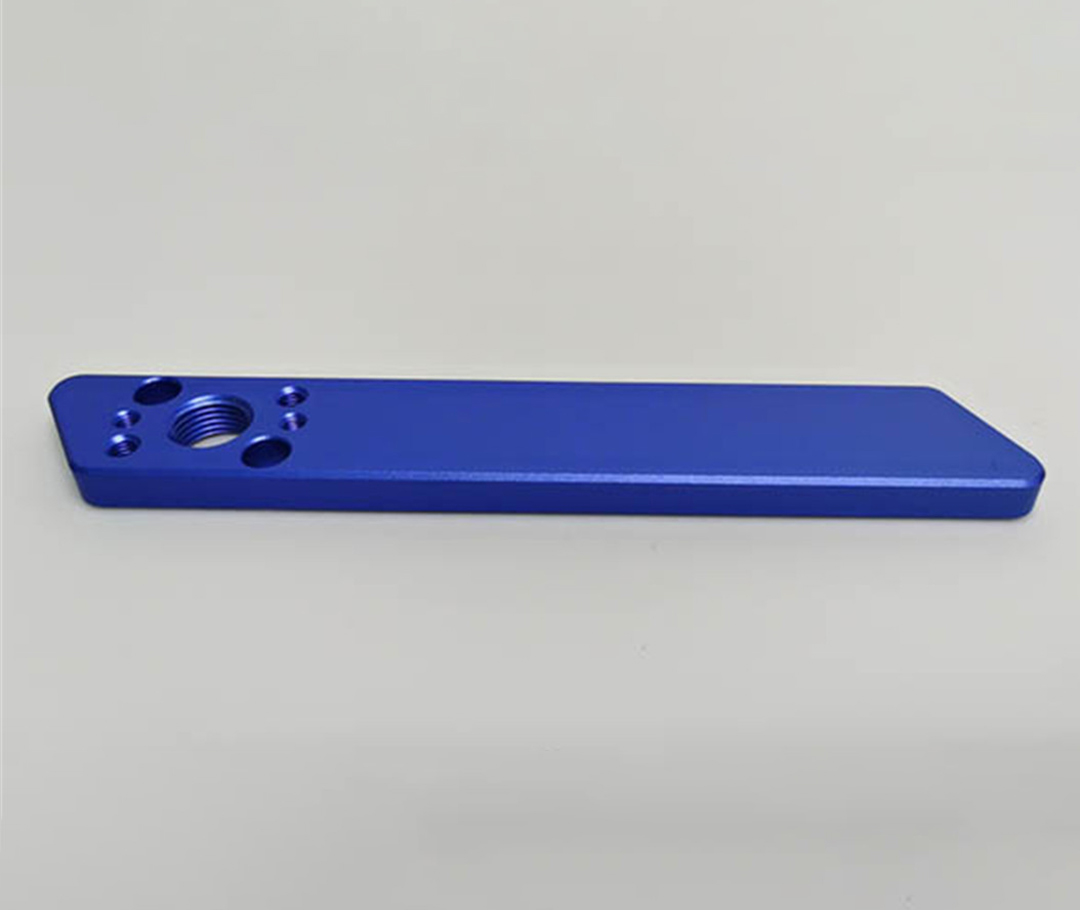

Likhetho tsa ho qetela tsa CNC le tsa Post-processing

Ho qeta bokaholimo ke mohato oa ho qetela oa machining oa CNC.Ho qeta ho ka sebelisoa ho tlosa mefokolo ea botle, ho ntlafatsa ponahalo ea sehlahisoa, ho fana ka matla a eketsehileng le ho hanyetsa, ho lokisa conductivity ea motlakase, le tse ling tse ngata.

● Joaloka Mochini

● Anodizing (Mofuta oa II & Mofuta oa III)

● Ho roala ka phofo

● Electroplating

● Ho qhomisa lifaha

● Ho oa

● Ho ba le takatso e matla

● Chemical Film(Chromate Conversion Coating)

Sheba Mehlala e meng ea likarolo tsa rona tsa CNC Mechine

Melemo ea ho Odara likarolo tsa Mochine oa CNC ho tsoa ho Star Machining

Phetoho e potlakileng:Maikutlo a potlakileng bakeng sa RFQ nakong ea lihora tse 24.E sebelisa mechini ea morao-rao ea CNC, Star Machining e hlahisa likarolo tse nepahetseng haholo, tse fetohang kapele ka matsatsi a 10.

Nepahalo:Star Machining e fana ka likhetho tse fapaneng tsa mamello ho latela maemo a ISO 2768 le ho tiisa le ho feta ho latela kopo ea hau.

Khetho ea thepa:Khetha linthong tse fetang 30 tsa tšepe le polasetiki kamoo u hlokang.

Liphello Tse Tloaelehileng:Khetha ho tsoa mefuteng e fapaneng ea likarolo tsa tšepe le likarolo tsa polasetiki, tse hahiloeng ka mokhoa o hlakileng.

Phihlelo:Baenjiniere ba rona ba ruileng ba nang le boiphihlelo ba tla u fa maikutlo a potlakileng a DFM.Star Machining e na le lilemo tse fetang 15 tsa taolo ea tlhahiso.Ho na le lik'hamphani tse likete le merero eo re e sebelelitseng liindasteri tse fapaneng, linaheng tse fetang 50 tseo re li rometseng.

Taolo ea Boleng:Lefapha la rona la QA le etsa tiisetso e matla ea boleng.Ho tloha thepa ho isa thomelong ea ho qetela ea sehlahisoa re etsa tlhahlobo e tiileng ka maemo a machabeng.Likarolo tse ling re li etsa tlhahlobo e felletseng joalo ka kopo ea bareki.

Thomello e potlakileng:Ntle le morekisi ea khethiloeng, re boetse re na le moemeli oa rona oa DHL/UPS le morekisi ea ka romellang likarolo tsa hau ka thomello e potlakileng le theko e utloahalang.