Die casting ke eng

Die casting ke ts'ebetso ea ho lahla tšepe e khetholloang ka tšebeliso ea sekoti sa hlobo ho kenya khatello e phahameng ho tšepe e qhibilihisitsoeng.Hangata hlobo e etsoa ka lialloi tse matla, e leng mokhoa o batlang o tšoana le oa ente.Bongata ba li-die castings ha li na tšepe, tse kang zinki, koporo, aluminium, magnesium, lead, tin, le li-alloys tsa lead-tin le li-alloys tsa tsona.Ho ipapisitsoe le mofuta oa ho lahlela lefu, mochini o batang oa mochini oa ho lahla kapa mochini o chesang oa kamore e chesang oa hlokahala.

Die casting e loketse ka ho khetheha bakeng sa ho etsoa ha palo e kholo ea li-castings tse nyenyane le tse mahareng, kahoo ho lahlela lefu ke mokhoa o sebelisoang ka ho fetisisa oa mekhoa e sa tšoaneng ea ho lahla.Ha ho bapisoa le mekhoa e meng ea ho lahla, "die casting" e na le sebaka se bataletseng le ho lumellana ho phahameng.

Ho sebetsa joang ka lefu

Ka mantsoe a bonolo, tšepe die casting e sebetsa ka ho sebelisa khatello e phahameng ho qobella tšepe e qhibilihisitsoeng ka sekoting sa hlobo, se entsoeng ka litšepe tse peli tse thata.Hang ha sekoti se tlatsitsoe, tšepe e qhibilihisitsoeng ea pholile ebe e tiea, 'me e shoa e buleha e le hore likarolo li ka ntšoa.Leha ho le joalo, ts'ebetsong, ho na le mehato e mengata ts'ebetsong, 'me baenjiniere ba nang le tsebo ba hlokeha ho sebelisa lisebelisoa tsa ho lahla.

Mona re tla arola mokhoa oa ho lahlela lefu ka mekhahlelo e meraro:

1. Ho etsa hlobo

2. Ho Lahlela (Filling-Injection-Cavity Ejection- Shakeout)

3. Post-machining

Khamphani ea Star Machining Technology e fana ka litšebeletso tse felletseng tsa Die-Cast tharollo.Matla a rona a kenyelletsa bokhoni ba ho etsa moralo oa lefu le ho etsa lintho ka har'a sehlopha sa litsebi tsa boenjiniere, ho qhibiliha le ho kopanya ka tlung, ho lahla, ho qeta, ho sebetsa ka mechine le ho kopanya.

Bokhoni ba rona ba ho etsa tlhahiso bo re lumella ho hlahisa, ho qeta le lisebelisoa tsa mochini oa aluminium die cast ho kopana le mefuta e mengata ea litlhaloso tsa bareki.Ho tloha ho meralo e bonolo ho isa ho e rarahaneng e sebelisang li-alloys tse 380, 384 le B-390.Boitseanape ba rona le boiphihlelo ba rona bo re thusa ho fana ka mamello e haufi, li-angles tse fokolang tsa moralo, pheletso e ntle le matla a phahameng ka botenya bo fokolang ba lebota bo hlokahalang, ka theko e tlase.

Re sebelisa boenjineri ba nako e le 'ngoe mme re nka karolo molemong oa moralo ho netefatsa PPM e ntle haholo le melemo ea litšenyehelo ho moreki bophelo bohle ba lenaneo.Ts'ebetso ea ho lahla lefu e ipapisitse le tlhahiso e potlakileng e lumellang hore palo e phahameng ea likarolo tsa lefu e hlahisoe ka potlako haholo le ka litšenyehelo tse ngata ho feta mekhoa e meng ea ho lahla lefu.Mechini ea ho lahla ea aluminium e tšoarella lipakeng tsa 50,000 le 400,000, ho latela ts'ebeliso le sehlopha sa sesebelisoa se hlahisoang.Kopanya lintlha tsena 'me u tla bona hore na hobaneng aluminium die casting e fetohile khetho e ratoang ke bareki lefatšeng ka bophara.

E le setsi se ka sehloohong sa khatello e phahameng ea aluminium die caster, karolo e 'ngoe le e' ngoe ea k'hamphani ea Star Mahcining Technology e na le tsebo ea ho hlahisa lihlahisoa tsa boleng bo phahameng ba aluminium tse hlokang mamello e haufi, khatello ea khatello, qetello e ntle ea holim'a metsi, le ts'ebetso e fapaneng ea bobeli.Karolo e 'ngoe le e' ngoe ea k'hamphani ea Star Machining Technology e na le phihlello e felletseng ea lisebelisoa tse etellang pele tsa ts'ebetso ea khoebo e kopaneng ea Star Machining.Ka kakaretso, karolo e 'ngoe le e' ngoe ea Star Machining e hlahisa li-alloys tse ngata, e etsa mesebetsi e mengata e fapaneng ea bobeli, 'me e na le litsi tsa machining tsa CNC bakeng sa likarolo tseo re li lahlelang.

Melemo ea Die Casting

● Ho nepahala ha Dimensional: Mekhoa ea ho etsa li-die cast e lumella ho etsoa ha likarolo tse ts'oanang le tse tsitsitseng, ha li ntse li boloka mamello e hlokahalang, ka mokhoa o nepahetseng ho feta mekhoa e meng e mengata ea tlhahiso ea bongata.

● Thepa e ikhethang: Ho tšoarella ho phahameng le ho hanyetsa mocheso oa lihlahisoa tsa die-cast.

● High-Speed Production e lumella ho etsa likete-kete tsa li-castings tse tšoanang ntle le tlhokahalo ea mekhoa e meng ea ho qetela ea ho qetela ea mochine.

● Ho boloka litšenyehelo nako e telele ea lisebelisoa tsa lisebelisoa ho fella ka tlhahiso ea likarolo tse nang le theko ea tlhōlisano ea 'maraka.

● Li-geometri tse rarahaneng: Lihlahisoa tsa "die-casting" li matla ebile li bobebe ho feta lihlahisoa tse bapisoang tse entsoeng le mekhoa e meng ea ho lahla.Ho feta moo, "die casting" e fihlella marako a masesaane le a matla, a sa hlahisoeng habonolo le mahlale a mang a tlhahiso.

● Likarolo tse entsoeng ka die-cast li etsa hore ho be le karolo e le 'ngoe, e se nang likarolo tse arohaneng, tse tiileng kapa tse kopantsoeng, tse fanang ka matla le botsitso bo eketsehileng ho likarolo tse entsoeng.

● Die casting e lumella ho etsoa ha lihlahisoa tse nang le mekhoa e mengata ea ho qeta, e kang libaka tse boreleli kapa tse entsoeng, tse lumellang ho roala kapa ho roala ntle le ho hloka litokisetso tse rarahaneng.

● Die casting technologies e khona ho hlahisa likarolo tse nang le likarolo tsa fastening, baokameli, li-tubes, masoba, likhoele tsa ka ntle le li-geometri tse ling.

Die Casting Applications

Die casting ke ts'ebetso e matla, e feto-fetohang e loketseng likarolo tse fapaneng, ho tloha ho likarolo tsa enjine ho isa matlong a elektroniki.Mabaka a ho feto-fetoha ha mefuta-futa ea "die casting" a kenyelletsa sebaka sa eona se seholo sa moaho, mefuta e mengata ea likhetho, le bokhoni ba ho etsa likarolo tse qaqileng, tse phetoang, tse nang le marako a masesaane.

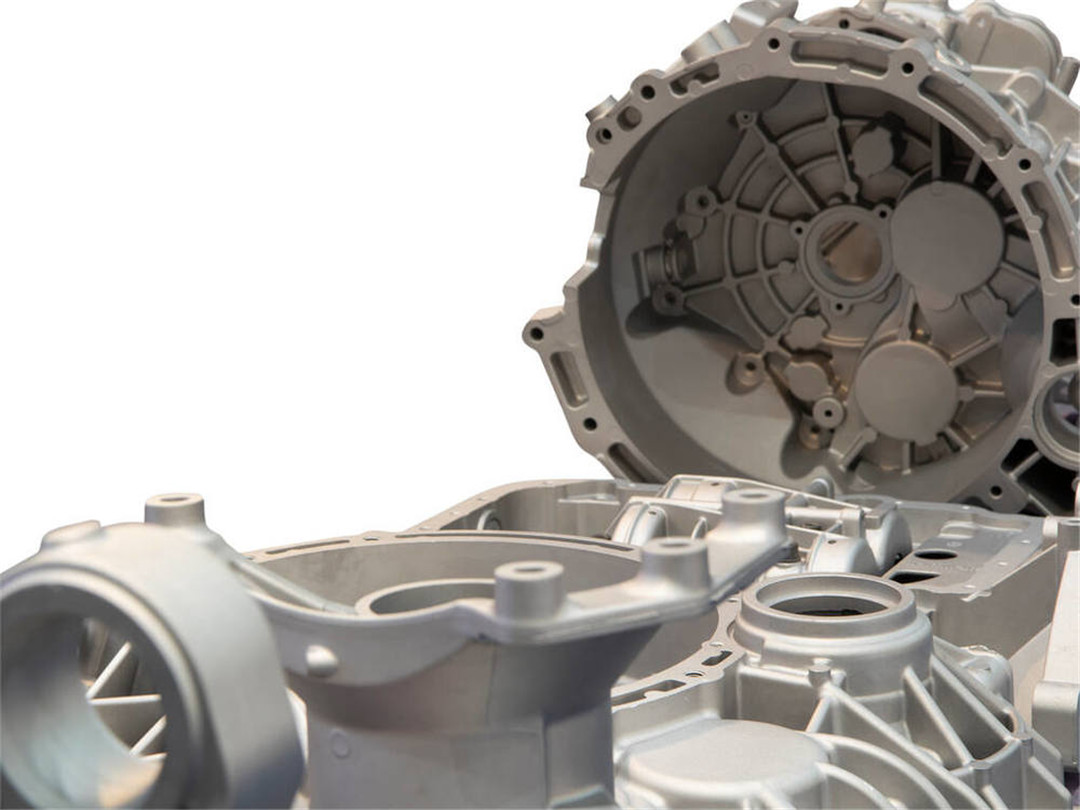

Tsa makoloi: Aluminium die casting e tumme indastering ea likoloi kaha e khona ho hlahisa likarolo tse bobebe joalo ka lisilindara tsa hydraulic, li-brackets tsa enjine le mekotla ea li-gearbox.Zinc die casting e loketse mafura, mariki le likarolo tsa ho tsamaisa matla, ha magnesium die casting e sebetsa bakeng sa liphanele le liforeimi tsa setulo.

Sepakapaka: Joalo ka indastering ea likoloi, bafani ba likarolo tsa sefofane ba sebelisa aluminium die casting ho etsa likarolo tse bobebe tse bonts'ang mocheso o phahameng le ho hanyetsa ho bola.Likarolo tse bobebe li fokotsa tšebeliso ea mafura.

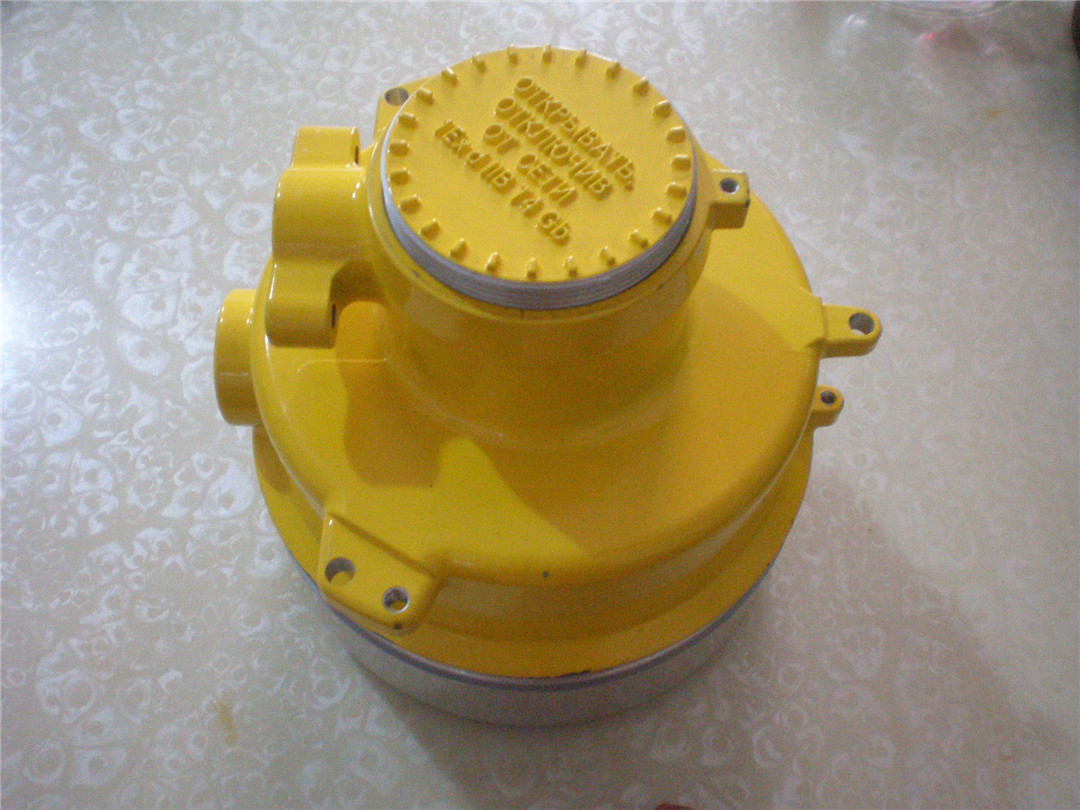

Matla: Likarolo tse lahlelang lefu lekaleng la oli le khase li kenyelletsa li-valve, likarolo tsa filtration, le li-impellers.Likarolo tsa matla a ka nchafatsoang joalo ka li-blade tsa turbine tsa moea le tsona li ka etsoa.

Tsa elektroniki: Die casting e atile ho lisebelisoa tsa elektronike, kaha e sebelisoa bakeng sa lintho tse kang liphaello, matlo le lihokelo.Likarolo tsa ho lahla li ka boela tsa etsoa ka lisinki tsa mocheso tse kenyelletsoeng, tse hlokahalang bakeng sa lisebelisoa tse ngata.Magnesium die casting e tumme bakeng sa likarolo tse sireletsang tsa RFI EMI tse tšesaane, ha aluminium die casting bakeng sa likarolo tsa leseli la LED e atile.(Die casting bakeng sa matlo a LED hangata a sebelisa motsoako o kang A383.)

Kaho: Indasteri ea kaho e sebelisa aluminium die casting bakeng sa meaho e meholo joalo ka liforeimi tsa moaho le lifensetere.

Boenjiniere: Lisebelisoa tsa ho phahamisa, lisebelisoa tsa mochini le lisebelisoa tse ling hangata li na le likarolo tsa die cast.

Bongaka: Ho tsa bophelo bo botle, die casting e ka sebelisoa bakeng sa ho beha leihlo likarolo tsa sesebelisoa, lisebelisoa tsa ultrasound le lintho tse ling.

Lisebelisoa tsa Aluminium Die casting

Aluminium ke e 'ngoe ea litšepe tse ka sehloohong tsa ho lahla, 'me lisebelisoa tsa aluminium li sebelisoa ka kamoreng e batang.Li-alloys tsena hangata li na le silicon, koporo le magnesium.

Li-alloys tsa aluminium die casting li bobebe 'me li fana ka botsitso bo botle ba mahlakore, e leng se etsang hore e be khetho e ntle bakeng sa likarolo tse rarahaneng, tse nang le likarolo tse ntle.Melemo e meng ea ho lahla aluminium e kenyelletsa ho hanyetsa kutu e ntle, ho hanyetsa mocheso, le mocheso le motlakase.

Li-alloys tse tloaelehileng tsa die casting aluminium li kenyelletsa:

380: Motsoako oa aluminium oa sepheo se akaretsang o lekanyang bokhoni le thepa e ntle ea mochini.E sebelisoa mefuteng e mengata e fapaneng ea lihlahisoa, ho kenyeletsoa masakaneng a enjine, thepa ea ka tlung, likabelo tsa lisebelisoa tsa elektroniki, liforeimi, lihato, mekotla ea li-gearbox le lisebelisoa tsa motlakase.

390: Alloy e nang le khanyetso e ntle ea ho apara le ho hanyetsa ho sisinyeha.E ntlafalitse ka ho khetheha bakeng sa "die casting" ea li-block tsa enjine ea likoloi hape e loketse 'mele ea li-valve, li-impellers le matlo a pompo.

413: Motsoako oa aluminium o nang le thepa e ntle ea ho lahla.E na le khatello e ntle ea khatello 'me ka hona e sebelisetsoa lihlahisoa tse kang hydraulic cylinders, hammoho le likarolo tsa meralo le lisebelisoa tsa indasteri ea lijo le lebese.

443: The ductile ka ho fetisisa ea die casting aluminium alloys, motsoako ona o loketse thepa ea bareki, haholo-holo e hlokang deformation ea polasetiki ka mor'a ho lahla.

518: Alloy aluminium ea ductile e nang le khanyetso e ntle ea kutu.E sebelisoa lihlahisoa tse fapaneng, ho kenyeletsoa lisebelisoa tsa lisebelisoa tsa sefofane, lisebelisoa tsa mekhabiso, le likarolo tsa escalator.

Kakaretso ea Litharollo bakeng sa Likarolo tsa Precision Die Cast le Dies

Haeba u na le moralo o rarahaneng oa likarolo, re ka u thusa ho o fetola hore e be oa nnete.Ka thepa e nepahetseng, tsebo e matla ea botekgeniki, le ho tsepamisa maikutlo holim'a boleng, Ho tloha ho moralo oa lisebelisoa ho fihlela qetellong le ho isa thomelong, re netefatsa hore morero o mong le o mong o phetheloa ka mokhoa o phahameng le hore litaelo tsa hau li fanoa ka nako nako le nako.Re sebeletsa likoloi, motlakase, thepa ea ka tlung, lihlahisoa tsa indasteri, lihlahisoa tsa hydraulic, le mefuta e mengata ea liindasteri.

Ho bona likarolo tse ling tsa "die casting" tseo re li hlahisitseng mona…