Seo re se etsang

Star Machining Technology ke setsebi sa moetsi oa hlobo, se sebetsanang ka ho khetheha le ho bōptjoa ha hlobo e kholo le e rarahaneng, re fana ka tharollo ea hlobo e le 'ngoe, e kenyelletsang sebopeho sa mochine oa motsoako, moqapi oa hlobo, tlhahiso ea hlobo, tlhahiso ea polasetiki kapa ea ho lahla le lits'ebeletso tsa bobeli tsa ts'ebetso.

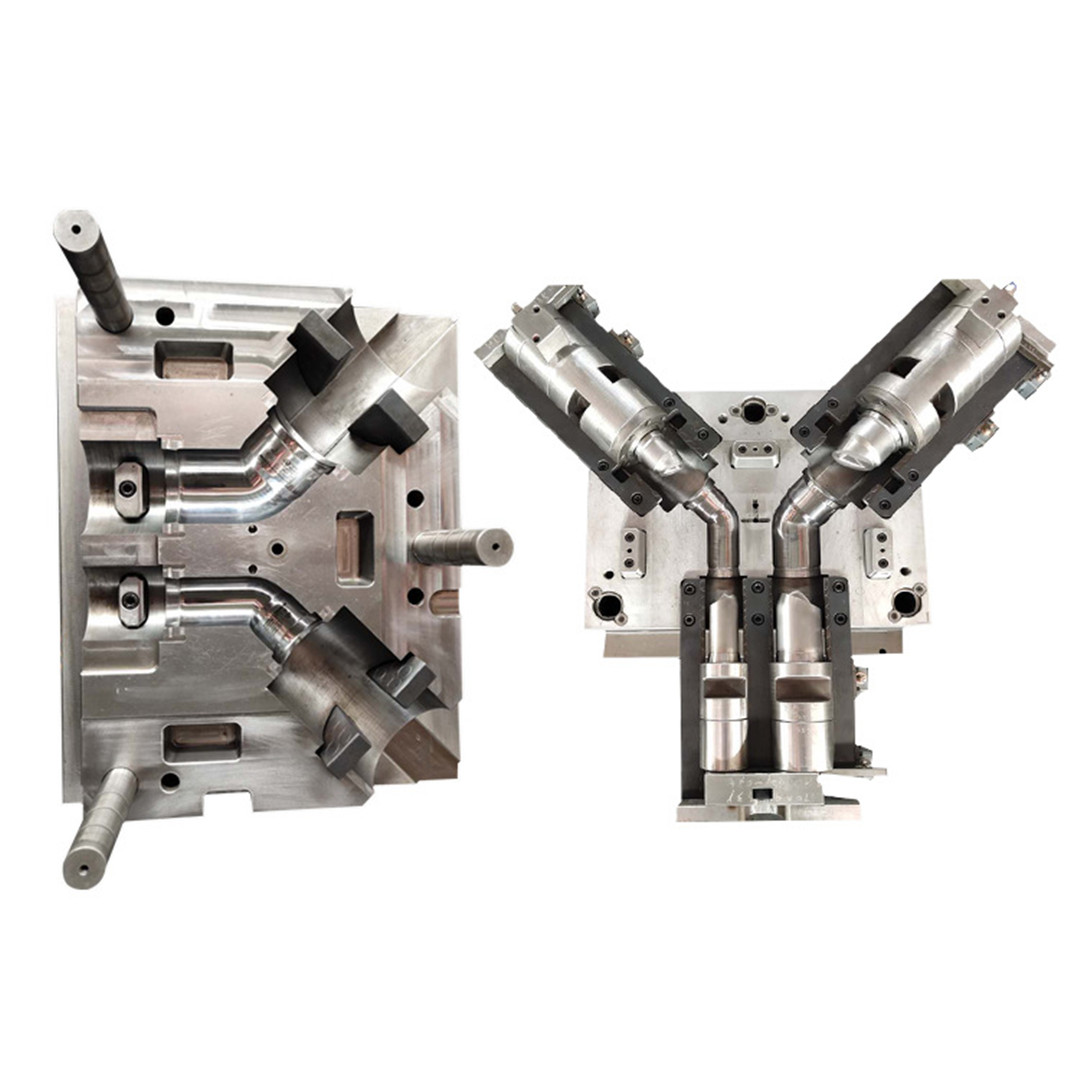

Ho Star Machining Technology, re na le boiphihlelo bo tebileng ba ho rala le ho hlakisa kaho ea hlobo ea aluminium ea diecast le hlobo ea ente.Re qala ho etsa hlobo esale pele ka ho sebetsa le uena ho tseba hore na moetso o na le bokhoni bofe.Hape re tla thusa ho theha litekanyetso tsa ts'ebetso bakeng sa karolo e felileng.Ho kenya letsoho hona pele molemong oa moralo le tlhahlobo ea hlobo ea die casting ho thusa ho netefatsa boleng ba sehlahisoa.Re ka hlahisa meralo e felletseng ea lisebelisoa, likopi tsa likarolo le litlhaloso ho tsoa ho mofuta oa hau, kapa lifaele tsa hau tsa 2D kapa 3D CAD.Baetsi ba rona ba hlobo ba hloahloa ba u fa tse ntle ka ho fetesisa tsa lefatše ka bobeli: ts'ebetso e tsoetseng pele le lisebelisoa matsohong a litsebi tsa mesebetsi ea matsoho tse nang le boiphihlelo.Moetso oa rona o nepahetseng oa moralo le bokhoni ba rona ba ho aha bo nepahetseng bo fetolela mokhoa oa tlhahiso o hlahisang likarolo tsa boleng bo holimo.Ha o laela Star Machining Technology ho aha hlobo ea hau, o tiisetsoa ka likarolo tse nang le ts'ebetso e tsitsitseng le phaello e phahameng ho tsetelo ea hau ea lisebelisoa.

Hape rea utloisisa hore likarolo tse hlahelletseng, tse mamelloang ka thata, tse nang le linako tse matla tsa ho etella pele, li hloka lisebelisoa tsa boleng bo holimo-ho tloha tlhahisong ea pele bophelong ba sehlahisoa sa hau.Hore na re ntse re aha hlobo bakeng sa prototype e le 'ngoe kapa li-cavity tse ngata, hlobo e felletseng ea tlhahiso ea foreimi, lisebelisoa tse ikhethang li bohareng ba ts'ebetso ea Star Machining Technology's die casting molding le ente.

Bokhoni ba rona ba Boenjiniere bo kenyelletsa:

Moralo oa Karolo:Re hlahisa lihlahisoa tse etsang hore ho be bonolo ho sebelisa lisebelisoa

Tlhahlobo ea Phallo:Re etsa tlhahlobo ea phallo ea phallo ea polasetiki ka Moldex3D

Moqapi oa Mold:Meralo eohle e entsoe ho sebelisoa Creo Parametric

Lipatlisiso le Maemo:Re boloka laebrari ea litekanyetso tsa bareki ka bomong

Tlaleho ea Tsoelo-pele:Lichate le lintlafatso tsa khafetsa tsa tsoelopele li fumaneha

Phetisetso ea Boitsebiso ka Elektronike:FTP le li-attachments tsa imeile lia fumaneha

Boloka le ho ntlafatsa CAD

Mefuta ea hlobo eo re fanang ka eona

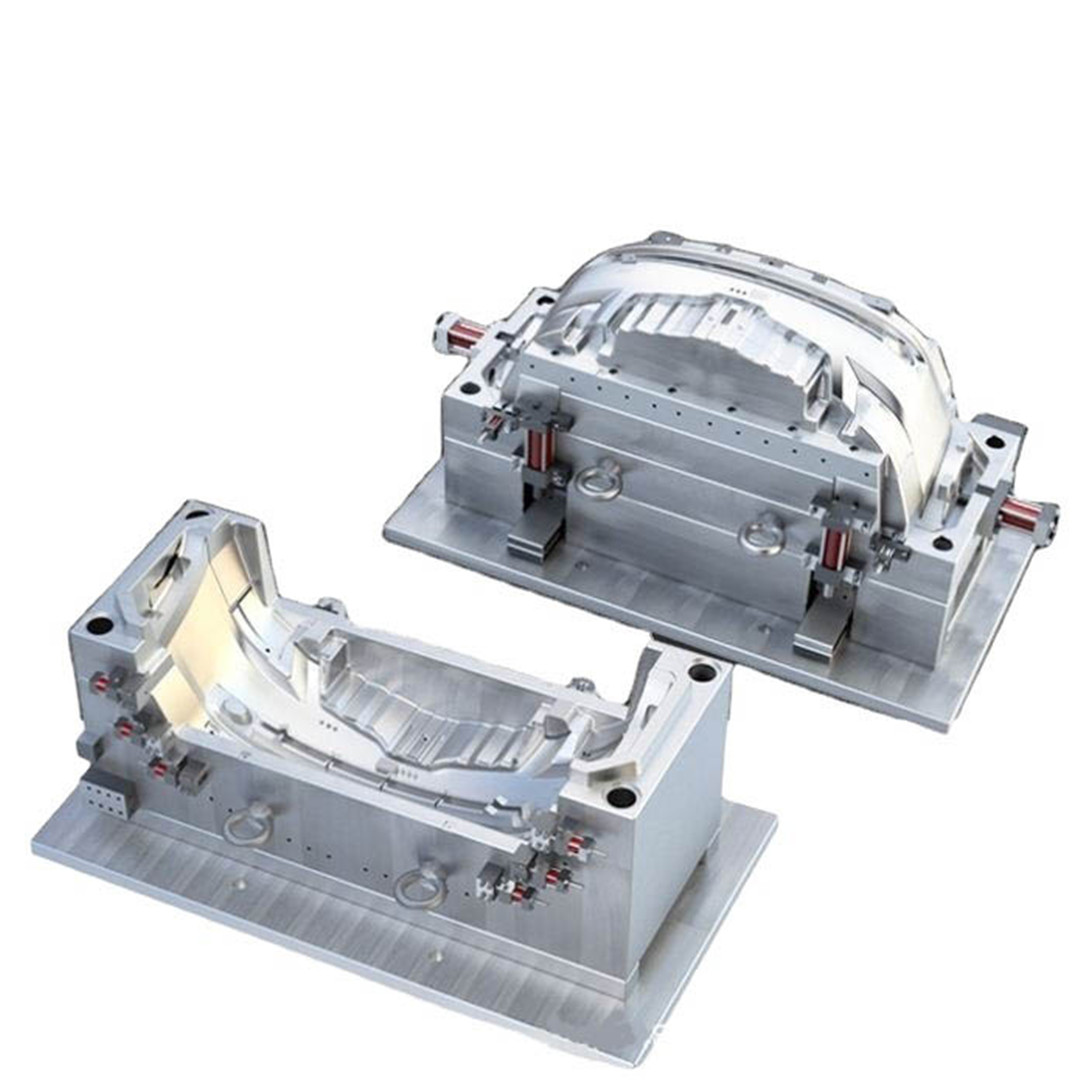

Die Casting Mold

Ho fapana le litsebi tse ngata tsa prototyping, re ka fana ka liforomo tsa tšepe (le tšebeletso ea ho ntša molumo o tlase ka balekane ba rona).Mefuta ena - eo hangata e entsoeng ka tšepe e thata - e ka sebelisoa ho etsa likarolo tsa aluminium, zinki, magnesium le litšepe tse ling tse se nang ferrous.

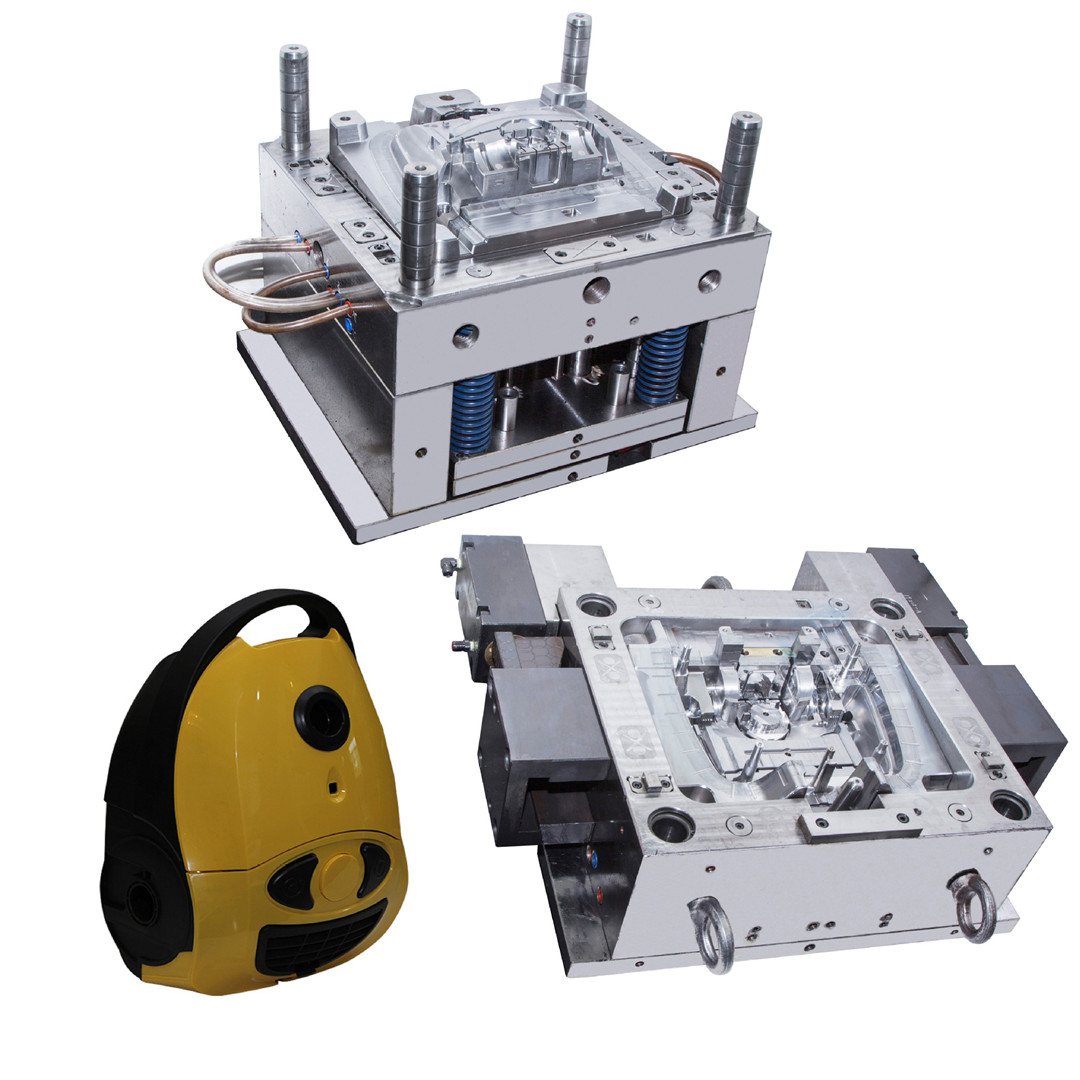

Polasetiki Ente Mouta

Mefuta ea ente ea polasetiki ke liforomo tsa aluminium kapa tsa tšepe tse sebelisetsoang ho etsa likarolo ho tsoa mefuteng e mengata ea polasetiki, ho kenyeletsoa li-nylon, li-acrylics, li-elastomers le lisebelisoa tse matlafalitsoeng joalo ka polyamide e tlatsitsoeng ka khalase.Mefuta e tloahelehileng ea polasetiki e ka nka lithunya tse pakeng tsa 10,000 le 1,000,000.

Mekhoa ea ho Etsa Mold

Ho etsa hlobo ke mokhoa o rarahaneng o hlokang tsebo le boiphihlelo bo holimo.Leha nyeoe e 'ngoe le e' ngoe e fapane, tatellano e tloaelehileng ea sete ea hlobo e ka tsamaea ka tsela e tjena:

1. DFM

Hang ha moreki a tiisa taelo ea hlobo, re tla qala ho etsa tlhahlobo ea pele ea likarolo ho fumana maikutlo a karolo ea karolo, maemo a liheke, joalo-joalo.

2. Moqapi oa hlobo le tlhahlobo ea ho phalla ha hlobo

Mohato oa bobeli o kenyelletsa tšebeliso ea software ea ho etsa mohlala e bolelang esale pele e re lumellang ho bona hore na lintho tse entsoeng ka ho qhibilihisoa li tla itšoara joang ha li kena ka har'a hlobo, e leng se lumellang hore ho ntlafatsoe ho eketsehileng ho moralo.

3. CNC machining le EDM

Re etsa liforomo tsa pele re sebelisa lisebelisoa tsa boleng bo holimo tsa machining, tse nang le polasetiki, tšepe, aluminium, joalo-joalo tse khethiloeng ke moreki.

4. T1 sampole

Ka liforomo tse sa tsoa etsoa, re etsa sampole ea T1 ho ba le pono e hlakileng ea hore na likarolo tse bōpiloeng tsa ho qetela tsa moreki li tla fella joang.

5. Ntlafatso ha ho hlokahala

Ho ipapisitsoe le tlhahlobo ea rona ea sampole ea T1, re hlahloba sebopeho sa hlobo mme re etsa liphetoho tse hlokahalang.

6. Qala tlhahiso le ho romella

Re etsa liforomo ho latela litlhaloso tsa ho qetela pele re li romella ho moreki.